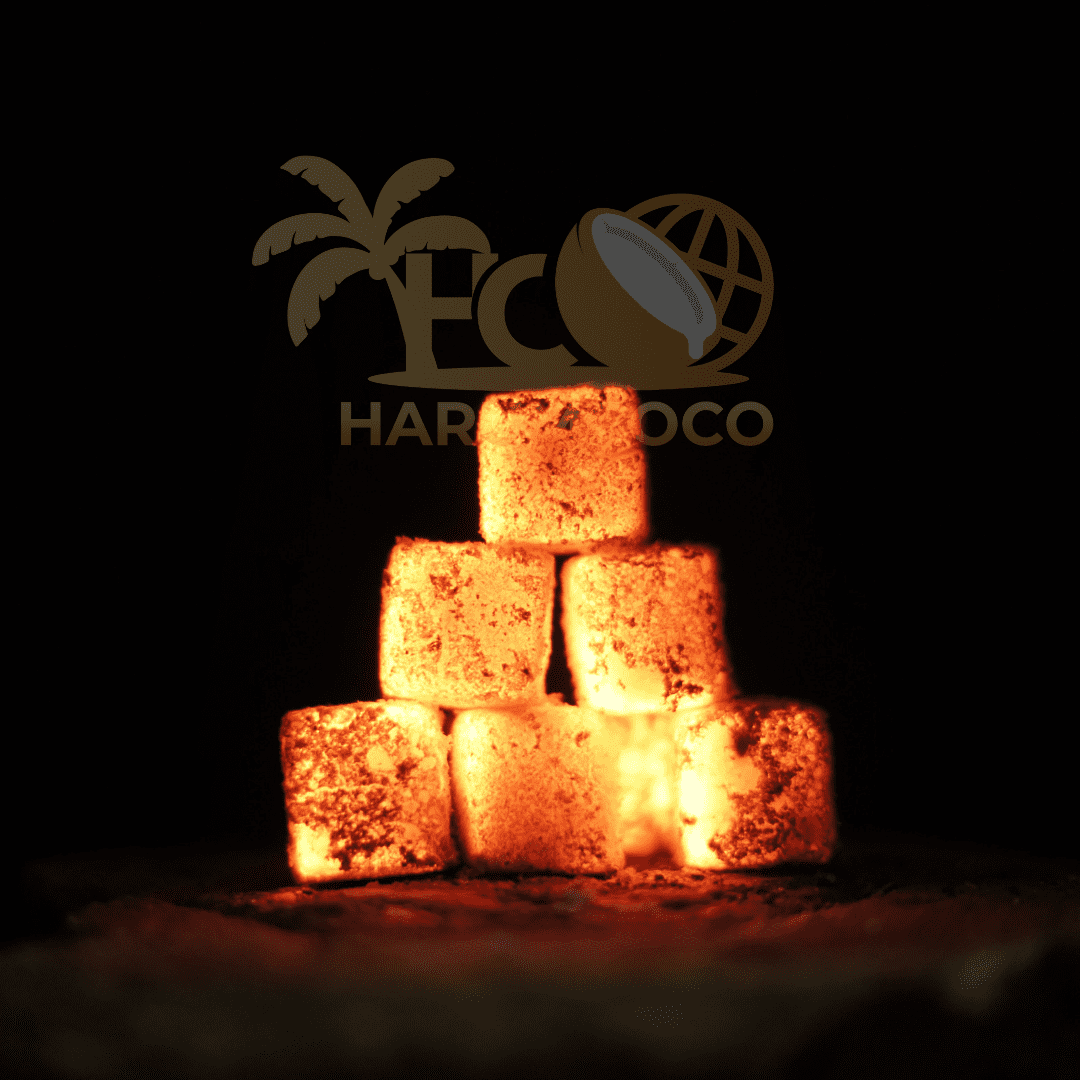

Every smooth, long-lasting shisha session starts with one simple ingredient — Coconut Charcoal. What seems like an ordinary cube of charcoal is, in reality, the result of a detailed process involving science, precision, and sustainability.

As global demand for eco-friendly and efficient shisha charcoal continues to rise, understanding how Coconut Charcoal is made gives both consumers and importers a deeper appreciation of the craftsmanship behind every piece.

At HarumCoco, we take pride in combining traditional expertise with modern production technology to produce charcoal that delivers perfect heat, minimal ash, and unmatched consistency.

Why Coconut Charcoal Is the Gold Standard for Shisha

Before exploring the manufacturing process, it’s worth knowing why Coconut Charcoal has become the preferred choice for hookah and shisha enthusiasts worldwide.

– Eco-friendly Origin – Made from discarded coconut shells, it uses renewable resources and helps reduce agricultural waste.

– Longer Burn Duration – Its high carbon density allows for extended burn time without frequent replacement.

– Low Ash Output – Keeps the hookah clean and the session smooth.

– Odorless & Tasteless – Ensures that only the true flavor of the shisha tobacco comes through.

Because of these advantages, Coconut has become the benchmark for quality — and Indonesia, with its vast coconut resources, leads global production.

Step 1 — Selecting the Finest Coconut Shells

The process begins with selecting mature, hard coconut shells sourced from local farmers across Indonesia. The best shells are dense, oil-free, and free of cracks — essential for producing high-quality Charcoal.

HarumCoco works closely with coconut suppliers who follow sustainable harvesting practices. This ensures that every shell used in our factory contributes to both environmental preservation and community welfare.

Step 2 — Carbonization (Turning Shells into Coconut Charcoal Briquettes)

The selected shells are then subjected to a controlled carbonization process, where they’re burned in limited oxygen to remove moisture and volatile compounds.

This step transforms the coconut shells into charcoal — rich in carbon, pure in form, and naturally hard.

At HarumCoco, we use advanced carbonization kilns that maintain stable temperatures, reducing smoke emissions while ensuring uniform quality. The result: charcoal with high fixed carbon content and low volatile matter — the perfect base for premium Charcoal briquettes.

Read More Shisha Charcoal Characteristics

VISIT US COCONUT CHARCOAL SHISHA FACTORY

Step 3 — Grinding and Filtering

Once the carbonized shells have cooled, they are ground into fine charcoal powder. The powder is then filtered to remove any impurities or uneven particles.

This refinement step is crucial, as consistent granule size ensures better compression, stability, and burning behavior in the final Coconut Charcoal product.

Step 4 — Mixing and Binding

The fine charcoal powder is mixed with a natural binder — typically food-grade tapioca starch and water. This step is done carefully to achieve the ideal balance between strength and density.

No chemical additives or synthetic binders are used at HarumCoco. Our focus is always on maintaining the natural purity of Coconut Charcoal, ensuring safety and performance for end users.

Step 5 — Shaping and Pressing Coconut Charcoal Briquettes

Next, the mixture is shaped using hydraulic or mechanical presses into cubes, hexagons, or custom forms depending on the customer’s market preference.

Each Coconut Charcoal briquette must have a perfect density and form to guarantee even burning and prevent cracks during use or transport.

HarumCoco’s advanced molding machines produce uniform charcoal blocks with precise dimensions — an essential feature for brand owners who prioritize visual appeal and consistency.

Step 6 — Drying Process Coconut Charcoal Briquettes

HarumCoco uses low-temperature drying systems that preserve the structural integrity of the Coconut Charcoal while ensuring it’s completely moisture-free before packaging.

This process can take up to 24–48 hours, depending on humidity levels and briquette size. The goal is to reach the optimal dryness level for safe export and long storage life.

Step 7 — Quality Inspection and Packaging

Before the charcoal leaves our factory, every batch undergoes a strict quality control inspection. Our experts test for:

– Burn duration

– Ash content

– Crack resistance

– Cube uniformity

– Odor and smoke test

HarumCoco’s Commitment to Sustainable Manufacturing

Our Coconut Charcoal manufacturing process is designed to minimize waste

Here’s how we ensure eco-friendly operations:

– 🌱 Zero wood cutting – 100% coconut shell-based raw material.

– 🌍 Energy efficiency – Controlled kilns reduce emissions and improve combustion efficiency.

This commitment not only meets international environmental standards but also supports sustainable livelihoods for Indonesian communities.

The Craftsmanship Behind HarumCoco’s Premium Coconut Charcoal

The journey of Coconut Charcoal — from shell to finished cube — is a combination of nature, science, and precision engineering.

At HarumCoco, we take pride in being more than just a factory — we are craftsmen of quality and partners in sustainability. Our production process reflects our dedication to excellence and our vision to make Indonesia the world’s benchmark for Coconut Charcoal.

If you’re a brand owner, distributor, or importer seeking a reliable partner with uncompromising quality, HarumCoco is ready to collaborate.

🔥 HarumCoco — Crafted in Indonesia, Trusted Worldwide.

Visit www.harumcoco.com to learn more about our manufacturing excellence and partnership opportunities.

Harumcoco – Coconut Charcoal Shisha Supplier

Harumcoco Indonesia