Indonesian Charcoal Manufacturers

In the competitive world of shisha charcoal supply, consistency is king. For shisha brands that want to build a loyal customer base, the charcoal they use must offer the same high-quality burn, clean flavor, and low ash content—every single time. One of the most trusted sources in the world for such dependable performance is Indonesian charcoal.

But what makes Indonesian manufacturers different? Why do foreign importers and brand owners continue to place their trust in Indonesia for their long-term charcoal needs?

Let’s explore the key factors that allow Indonesian charcoal producers to deliver stable, high-performance products batch after batch, year after year.

The Foundation: Quality Starts With the Coconut Shell

The journey toward stable, premium charcoal begins with the raw material—and Indonesia has a natural advantage.

As the world’s largest coconut producer, Indonesia has access to an abundant supply of dense, high-quality coconut shells, ideal for making superior charcoal. Unlike other regions that may import coconut husks or use lower-grade raw material, Indonesian manufacturers often work directly with coconut farmers to secure fresh, uncontaminated shells.

This direct sourcing ensures a stable input quality, which is crucial for maintaining consistent charcoal characteristics across production cycles.

Structured and Disciplined Manufacturing Process

One of the defining characteristics of successful Indonesian charcoal manufacturers is their commitment to structured production workflows. It’s not just about carbonizing coconut shells—it’s about controlling every detail of the process.

1. Carbonization Control

Carbonizing at the right temperature and for the right duration is critical. Indonesian factories typically use kilns or retort systems that allow for controlled, even carbonization. This eliminates raw smells, ensures complete burn-off of volatile matter, and produces a clean-burning base material.

2. Precise Milling and Mixing

Once carbonized, the charcoal is finely ground and mixed with natural binders. The balance must be perfect—too dry, and the briquette won’t hold; too wet, and it won’t burn properly. Indonesian factories have refined these ratios through years of production experience, resulting in dense, durable charcoal cubes with consistent burning behavior.

3. Hydraulic Pressing

Using industrial-grade hydraulic presses, manufacturers ensure uniform cube size, compression, and hardness. This ensures that every batch looks and performs similarly, reducing breakage and improving stacking and burning in end-user applications.

Quality Control: The Secret to Consistency

Even with great materials and machines, the secret to consistency lies in quality control (QC). High-level Indonesian manufacturers, especially export-focused ones, implement multi-stage QC protocols, including:

– Moisture testing after drying

– Ash content measurement

– Drop and pressure tests for strength

– Burn-time verification tests

– Visual inspection of cube shape and size

These controls aren’t done occasionally—they’re done per batch. This disciplined approach allows Indonesian suppliers to offer long-term clients predictable performance, shipment after shipment.

Read More Shisha Charcoal Characteristics

VISIT US COCONUT CHARCOAL SHISHA FACTORY

Why Indonesian Charcoal Factories Are Built for Export-Grade Quality

Unlike smaller operations in other countries that focus on local markets, many Indonesian charcoal factories are built with export standards in mind. This includes:

– Clean, organized production environments

– Trained teams who understand international buyer expectations

– ISO-aligned production documentation

– Packaging standards that match retail and white-label needs

These factors make Indonesian charcoal particularly appealing to foreign brands who want not just good charcoal—but a reliable supply chain partner.

How Indonesian Charcoal Protects Your Brand Image

Whether you’re a startup brand or a well-established distributor, your product’s consistency plays a huge role in how your brand is perceived. A charcoal cube that burns beautifully today but crumbles or smells next month creates doubt in your customer’s mind.

By sourcing from a highly consistent Indonesian supplier, you eliminate that risk. You can build a premium positioning around reliability, smoothness, and flavor protection. And when your brand becomes known for delivering a flawless hookah session—your customers stay loyal.

Real-World Impact: A European Brand’s Experience

A shisha brand based in Germany was previously importing charcoal from multiple countries, including Vietnam and India. They constantly dealt with complaints—“this batch smells,” “this one crumbles,” “why is it so ashy now?”

After switching to an Indonesian supplier that followed strict QC (yes—HarumCoco), they found peace of mind. Customer reviews improved, they received fewer complaints, and they even reduced waste due to less product breakage.

Now, they proudly write on their packaging:

“Made from premium Indonesian charcoal for a cleaner, smoother session.”

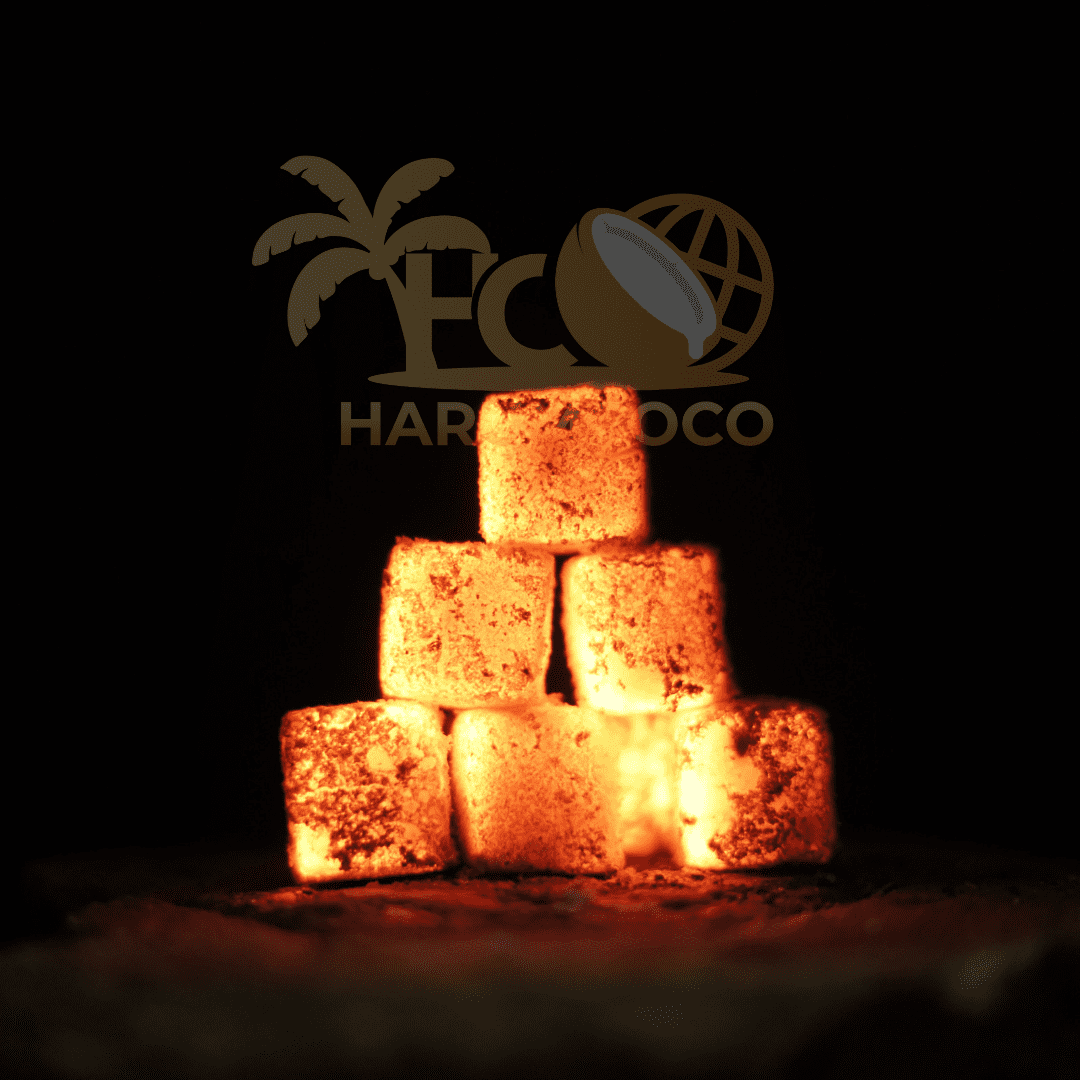

HarumCoco — Best Indonesian Charcoal Factory

Quality is not an accident—it’s a result of consistent effort, attention to detail, and deep respect for the product and the end user. That’s what makes Indonesian charcoal a smart, strategic choice for any brand aiming to stand out in the competitive shisha market.

At HarumCoco, we’re proud to be part of Indonesia’s legacy of charcoal excellence. We offer:

– Super premium coconut charcoal made from hand-selected raw materials

– Stable quality across all batches

– Strict QC, export packaging, and private label support

– A production system designed not for volume—but for trust

📩 Reach out today to learn how HarumCoco can help your shisha brand grow with dependable, world-class Indonesian charcoal.

Harumcoco – Coconut Charcoal Shisha Supplier

Harumcoco Indonesia