From Coconut Shells to Briquettes: The Process Behind Premium Coconut Charcoal

Coconut charcoal briquettes have become a cornerstone in industries such as shisha and barbecue, thanks to their superior performance and eco-friendly properties. Unlike traditional wood-based charcoal, coconut charcoal briquettes are made from a sustainable resource: coconut shells, which are often discarded as agricultural waste. This not only reduces environmental impact but also contributes to the circular economy by giving new life to byproducts of the coconut industry.

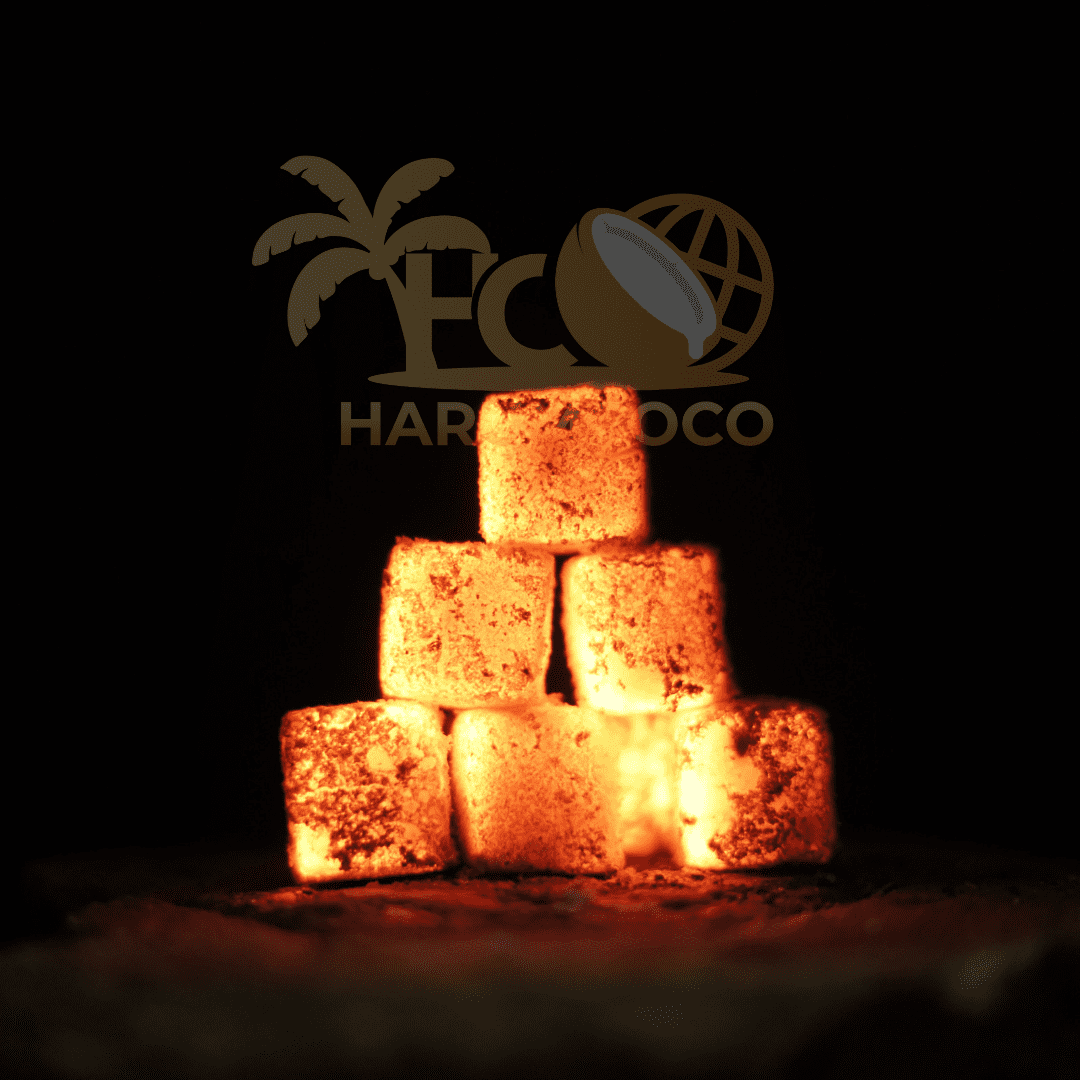

What makes coconut charcoal briquettes stand out is their long burn time, consistent heat output, and low ash production. These characteristics are essential for both casual users and businesses looking to provide the best experiences for their customers. However, achieving such quality isn’t a matter of luck—it’s the result of a meticulous, step-by-step manufacturing process that balances craftsmanship with modern technology.

In this article, we will explore the journey of turning raw coconut shells into the premium coconut charcoal briquettes that dominate the market today. From sourcing the finest materials to packaging the final product, every step plays a vital role in ensuring the briquettes meet the highest standards of quality and sustainability.

Whether you’re a curious consumer or a business looking to understand the value behind this product, this guide will provide you with a deeper appreciation for the effort and innovation involved in making coconut charcoal briquettes.

Step 1: Sourcing the Raw Material

The process begins with sourcing coconut shells, which are a byproduct of the coconut industry. Using coconut shells not only adds value to agricultural waste but also reduces reliance on traditional wood-based charcoal, preserving forests and promoting sustainability.

Key considerations in sourcing:

1. Ensuring the shells are dry and free from contaminants.

2. Collaborating with local farmers to maintain a steady supply of raw materials.

Step 2: Carbonization

The coconut shells are carbonized through a process known as pyrolysis. This involves heating the shells in a low-oxygen environment to convert them into charcoal.

– Temperature control: The shells are heated at temperatures between 400-700°C

– Result: The outcome is raw charcoal with high carbon content, which forms the base for premium briquettes.

Why it matters: Proper carbonization ensures minimal ash content and a consistent burn, which are crucial for high-quality briquettes.

Step 3: Crushing and Screening

Once carbonized, the charcoal is crushed into fine particles to create a uniform texture. This step ensures that the briquettes will compress evenly, resulting in a stable and durable product.

– Large pieces are broken down using industrial grinders.

– The crushed charcoal is then screened to remove impurities and achieve the desired particle size.

Read More Shisha Charcoal Characteristics

VISIT US COCONUT CHARCOAL SHISHA FACTORY

Step 4: Mixing with Binders

To form briquettes, the charcoal powder is mixed with natural binders, such as starch or tapioca. These binders ensure the briquettes hold their shape without crumbling.

– The ratio of binder to charcoal is carefully measured to maintain quality.

– Water is added to the mixture to create a moldable consistency.

VISIT US COCONUT CHARCOAL SHISHA FACTORY

Step 5: Compression and Molding

The mixture is fed into briquette-making machines, where it is compressed into uniform shapes, typically cubes or hexagons. This compression increases density, allowing for a longer burn time and higher heat output.

Quality control at this stage ensures:

– Uniform size and shape.

– Proper density for efficient burning.

Step 6: Drying and Curing

The freshly molded briquettes are then dried to remove excess moisture. This step is crucial for achieving a long shelf life and optimal burning performance.

– Sun drying: A traditional, eco-friendly method used in sunny climates.

– Kiln drying: Ensures consistent results in large-scale production.

Step 7: Packaging and Distribution

Once dried, the briquettes are packaged in airtight, moisture-resistant bags to preserve their quality during storage and transport. Premium brands also ensure attractive, informative packaging to appeal to customers.

Why This Process Matters

Each step in the production process is carefully designed to maximize the briquettes’ performance and environmental benefits. Key advantages of premium coconut charcoal briquettes include:

– Longer burn time: Ideal for shisha and grilling.

– Low ash residue: Easier cleanup and a cleaner smoking experience.

– Eco-friendly: Made from sustainable materials and a renewable resource.

Conclusion

The transformation of coconut shells into premium coconut charcoal briquettes is a testament to innovation and sustainability in the industry. By understanding the meticulous production process, you can appreciate the craftsmanship and quality that goes into every briquette.

Whether you’re a business owner or a consumer, choosing coconut charcoal briquettes means supporting eco-friendly practices while enjoying a superior product.

From Coconut Shells to Briquettes: The Process Behind Premium Coconut Charcoal

Harumcoco – Coconut Charcoal Shisha Supplier

Harumcoco Indonesia