If you’re in the shisha business, you already know that charcoal is not just charcoal. It’s the foundation of the entire experience. Yet, so many brands fall into the same trap—choosing the wrong charcoal shisha factory and paying the price in lost customers, bad reviews, and inconsistent sales.

Picture this: You’re at a high-end lounge, the ambiance is perfect, the hookah setup is premium, and then—bam! The charcoal starts crumbling, the heat is inconsistent, and the whole session is ruined. Sound familiar?

So what’s the one thing that separates the pros from the amateurs? Let’s dive in.

Why Your Charcoal Shisha Factory Defines Your Brand

Think about the biggest names in the shisha industry. Do you think they settle for any random supplier? No way. They know that the right charcoal supplier can make or break their business.

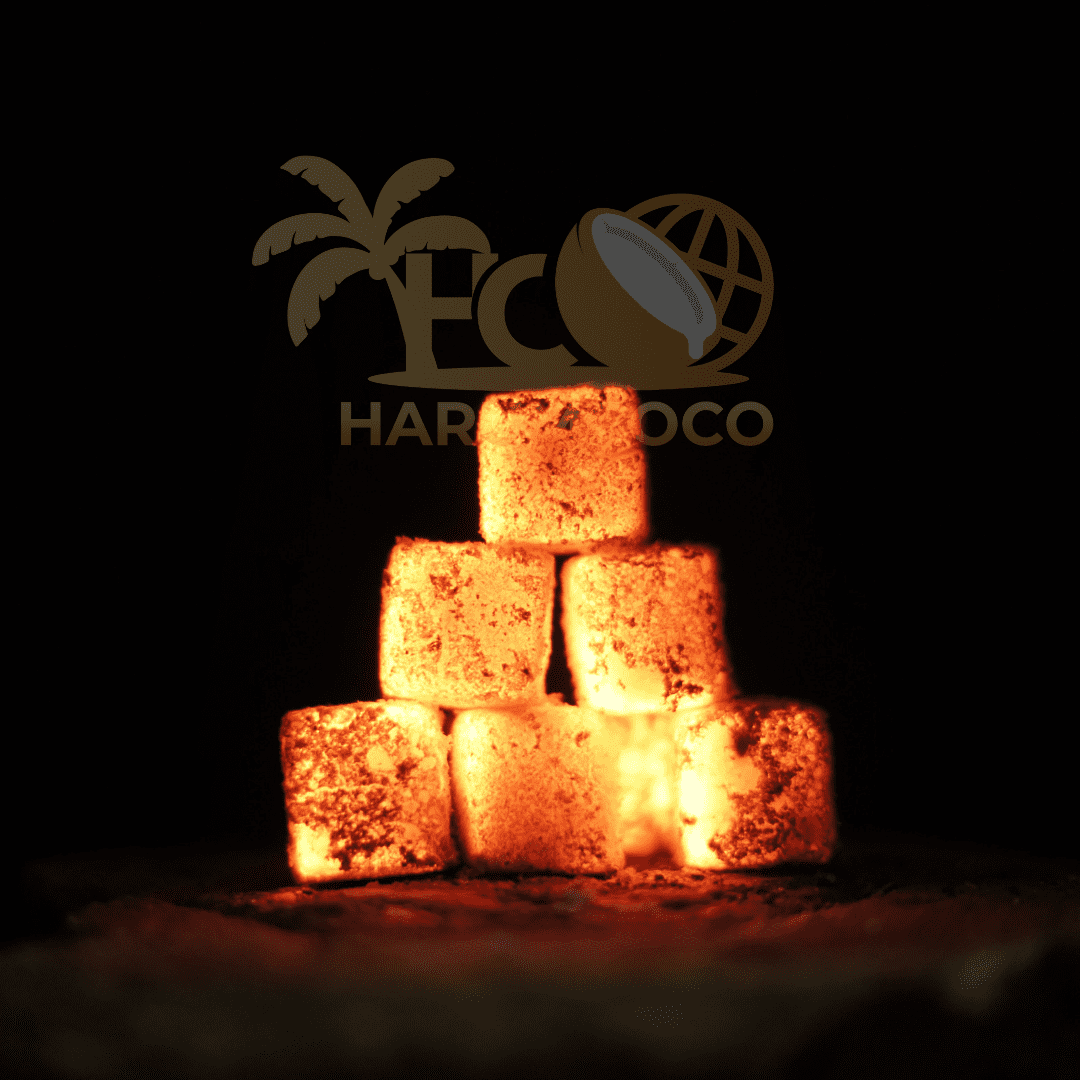

A high-quality charcoal shisha factory isn’t just about producing black cubes—it’s about consistency, performance, and reliability. If your charcoal burns too fast, creates excess ash, or has a weird aftertaste, your customers will notice—and they won’t come back.

A pro-level factory ensures:

– Perfectly compressed charcoal for a steady, long-lasting burn.

– Minimal ash production so your customers don’t have to clean up every 10 minutes.

– Zero additives or chemicals that ruin the natural flavor of the shisha.

The Difference Between a Good Charcoal Shisha Factory and a Great One

Here’s where things get real. Not all factories are created equal.

A mediocre factory will:

– Cut corners with low-quality coconut shells.

– Rush production, leading to weak, crumbly charcoal.

– Struggle to keep up with your orders, delaying shipments.

Meanwhile, a top-tier charcoal shisha factory will:

– Source the best raw materials for pure, natural charcoal.

– Use high-pressure molding machines to create ultra-dense briquettes.

– Implement strict quality control so every batch is identical.

The result? A premium smoking experience that keeps customers loyal to your brand.

How Technology is Changing the Charcoal Game

The shisha industry is evolving, and so is the way premium charcoal is made. Advanced charcoal shisha factories are now using cutting-edge technology to ensure better performance, lower emissions, and higher efficiency.

🚀 Infrared Heat Testing – Every batch undergoes precise heat testing to ensure it burns at the perfect temperature.

🌿 Eco-Friendly Carbonization – Factories are now using cleaner production methods to reduce environmental impact.

🔬 Automated Quality Control – AI-powered inspections ensure that only flawless charcoal cubes make it into your shipments.

This means more consistency, fewer headaches, and a product that truly stands out in the competitive shisha market.

What to Look for in a Charcoal Supplier

So, if you’re looking for a supplier, how do you know which charcoal shisha factory is the right one? Here’s what to check:

🔥 Raw Material Quality – Are they using 100% natural coconut shells?

🏭 Production Process – Do they use high-pressure machines and clean carbonization?

📦 Packaging & Logistics – Can they handle bulk orders without delays?

📝 Certifications – Do they meet international safety and environmental standards?

Choosing the right supplier is an investment in your brand’s reputation. Don’t cut corners—work with a factory that guarantees premium results.

Read More Shisha Charcoal Characteristics

VISIT US COCONUT CHARCOAL SHISHA FACTORY

Final Thought: What’s Your Move?

If you’re serious about growing your shisha brand, the choice is clear: work with a factory that delivers perfection—every single time.

Don’t settle for less. The biggest names in the industry didn’t—why should you?

🚀 Looking for a factory that guarantees premium, high-tech charcoal production? Let’s talk.

Harumcoco – Coconut Charcoal Shisha Supplier

Harumcoco Indonesia